Multiproduct Production takes a Giant Leap Forward with AMT’s Anysize Positioner Systems

Over the last decade, the manufacturing industry has undergone incredible changes, leaving production facilities scrambling to remain relevant and competitive. As rapidly evolving consumer markets demand an endless variety of different sizes and shapes for packaging and containers alike, adaptable conveyor systems have become a necessity.

Using the same production line to run different products was creating issues for plant managers and they reacted to endless product jams, unreliable retrofits and time-consuming changeovers. Adjustable guide rails were used as a way to keep products and containers moving efficiently, but early designs were plagued with flaws that effectively ruined all hope of profitability.

Early mechanical and pneumatic systems had guide rails moving on a series of actuators, but were unable to achieve the level of precision required of a high-volume conveyor system. Even the smallest deviations in position could prove to be catastrophic. If and when the ideal guide position was finally acquired, it was difficult to repeat, especially across independently-operating actuators. Positioners simply were not accurate or reliable. These problems were costly

at best, and threatening to the business at worst.

A New St

andard for Accuracy

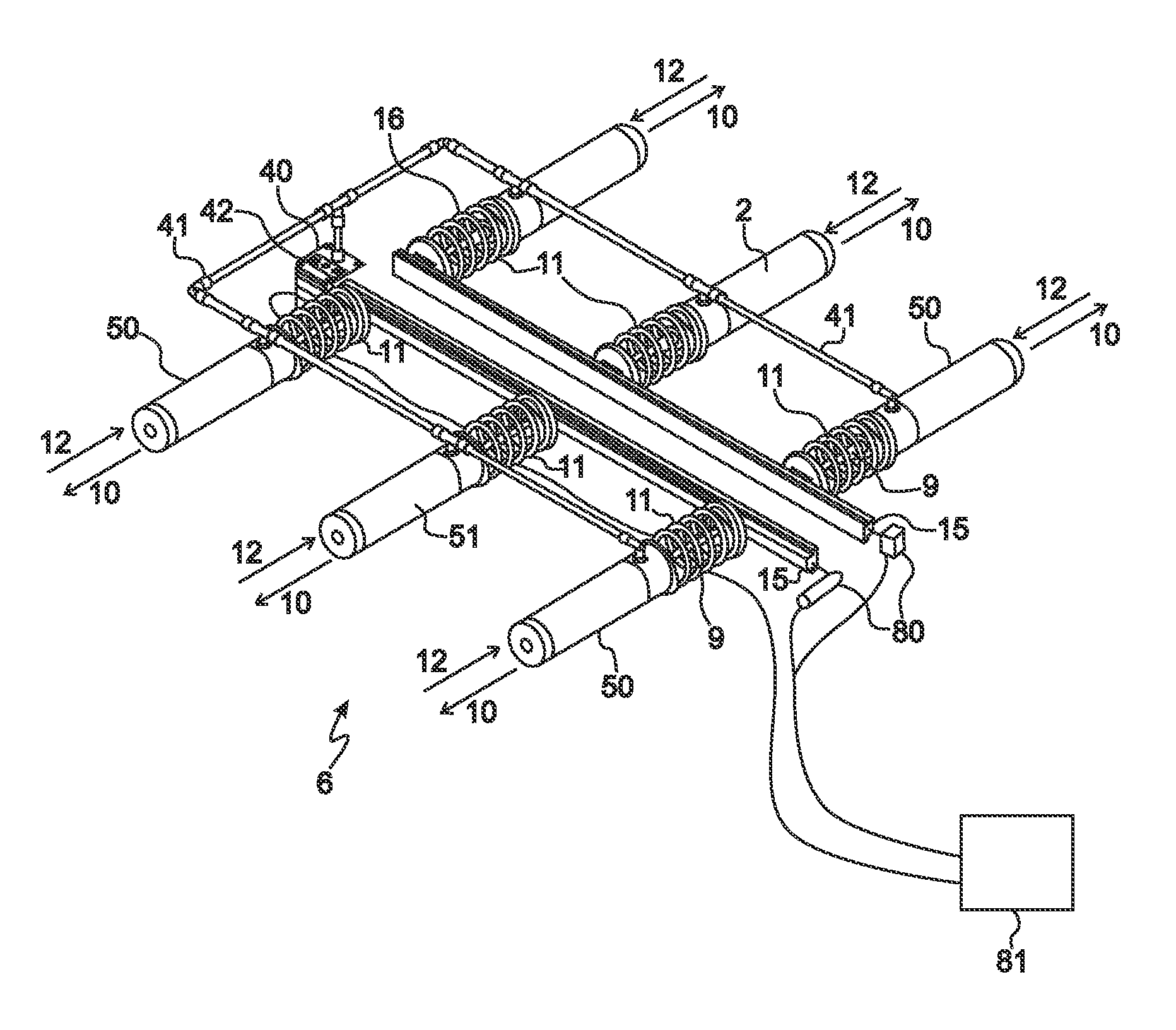

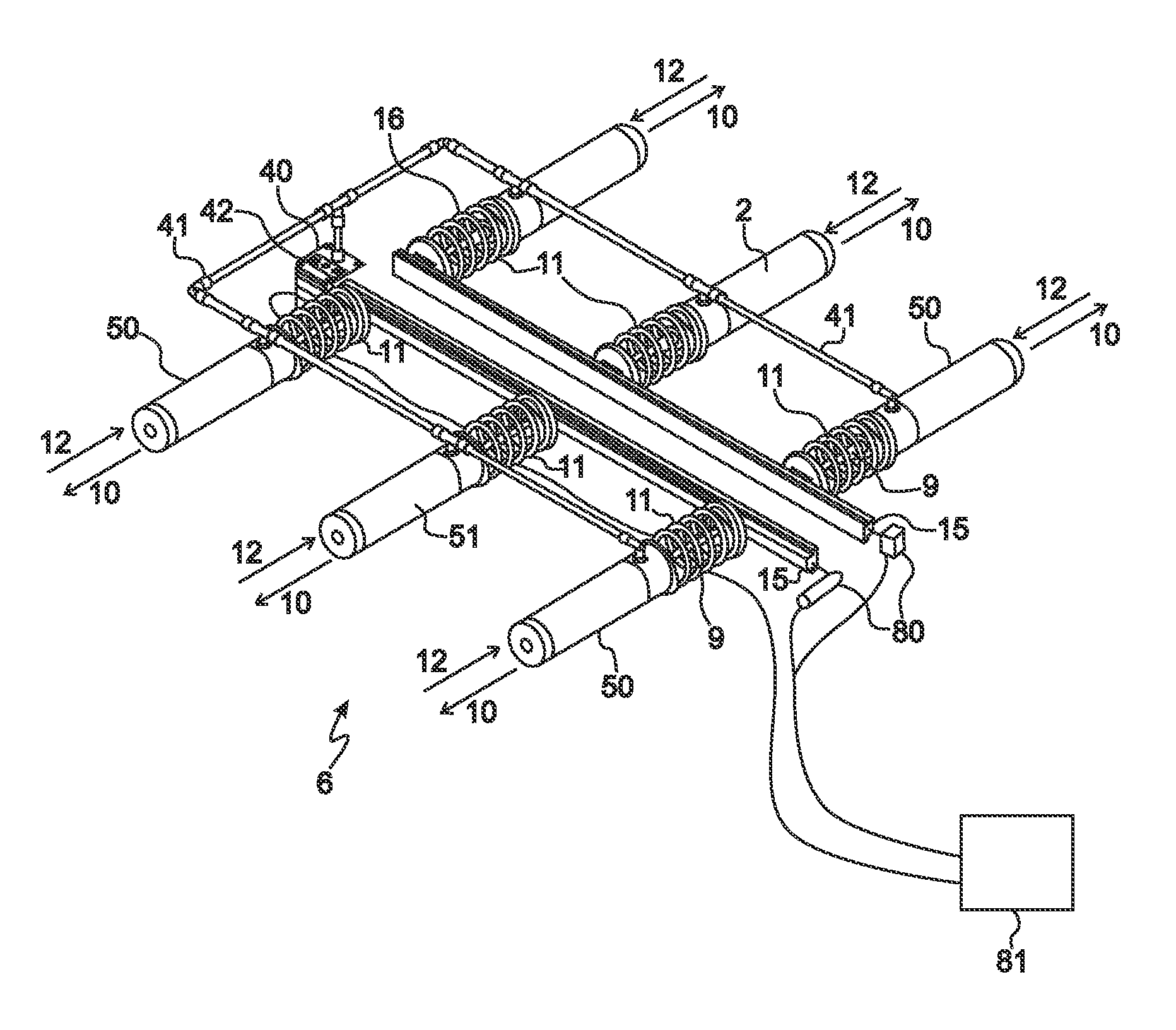

One of the most important innovations that AMT brought to the table was the use of a linear spring as a biaser, incorporated into a pneumatic piston for unprecedented accuracy. When a force is applied to the spring, it expands in proportion to that force. Double the force means double the position, and so on. By adjusting the force of air pressure pushing against a piston connected to the spring, it is possible to achieve positioning precision within 1 millimeter.

Simplified Control, Enhanced Capability

The ability to move multiple positioners in unison was another component of the new technology. Identical in construction and sharing pressure via a common airline, guide positioners could finally be set and repositioned without skewed rails and mismatched sections of rail. By regulating pressure to control positioners, the ground was laid for fluidic communication of more complex systems, with groups of positioners responding to different pneumatic inputs. Postioners could also be made to control other positioner groups, thus making two-dimensional positioning a reality.

The arrival of Anysize positioners and systems ushered in a new era of conveyor technology. With the ability to run on deck and neck ring air conveyor designs, as well as to be retrofitted on older conventional conveyors, entire facilities were no longer tied to one product. Multiple sizes and shapes could be run at full speed, with changeovers becoming a mere matter of recalling settings from a user interface.

Today, Anysize continues to set the standard in conveyor technology, with subsequent innovations helping to refine and specialize the functionality, pushing the envelope of what a modern production facility is capable of.

Read more about this and other AMT innovations on Google Patents. (link to https://patents.google.com/patent/US8132665B2/en?q=joe&inventor=pawelski&num=25&oq=joe+pawelski&sort=old)